Did you know that you can identify many engine problems just by removing and inspecting the spark plugs?.

Below are various images of plugs and some of the problems that can be identified based on spark plug appearance:

Below are various images of plugs and some of the problems that can be identified based on spark plug appearance:

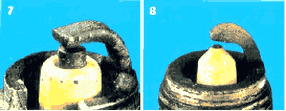

Images 1 & 2: These are normal looking spark plugs.

The insulator tip is grayish white, but could also be

grayish yellow to brown. This indicates the engine is in

good operating condition and the heat range of the

plug is correct.

The insulator tip is grayish white, but could also be

grayish yellow to brown. This indicates the engine is in

good operating condition and the heat range of the

plug is correct.

Images 3 & 4: Velvet-like, dull black carbon deposits on the insulator, electrodes and shell can be caused by any of the following: incorrect mixture, dirty air filter, faulty automatic choke, too cold a spark plug, or extreme stop & go driving conditions. To remedy this situation, make appropriate mixture adjustments, replace air filter or use a hotter spark plug in case of extreme stop & go driving conditions.

Images 5 & 6: The wet, shiny deposits shown on these spark plugs are oil. The excessive quantity of oil can result from worn cylinders, piston rings or valves. In a two stroke engine, it indicates an oil mixture that is too rich. To correct the problem, repair and/or replace worn parts. In any case, new spark plugs should be installed.

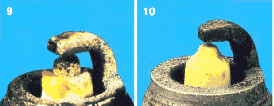

Images 7 & 8: The yellow insulator deposits shown here are from fuel additives containing lead. With higher load, the deposit becomes conductive and causes misfiring. New plugs should be installed, cleaning is ineffective.

Images 9 & 10: The brownish tint in the yellow glazed deposit is a combination of carbon and lead from fuel and oil additives. They accumulate on the insulator nose during slow driving conditions and, under hard acceleration, melt. As the plug cools, the deposits solidify. Again, cleaning and sandblasting are useless; install new spark plugs.

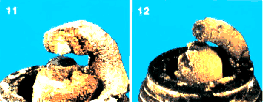

Images 11 & 12: The brownish, cinder-like deposits on the electrodes and insulator are ash residues from oil and gas additives. The alloying additives leave an unburnable ash in the combustion chamber and on the spark plug. In serious cases, it may be necessary to decarbonize the combustion chamber before installing new spark plugs.

Image 13: A melted electrode, with a white, blistered insulator tip indicates incorrect heat range or insufficient installation torque. Note: If the insulator is separated from the shell and the shell is discolored, insufficient installation torque is the cause. If the shell is not discolored, overtorquing is the cause. Spark plug misfiring will occur and engine damage can result. A thorough tune-up should be performed and before installing new spark plugs, check the appropriate application to insure proper heat range.

Image 14: The melting of the center electrode results from abnormal combustion; for example, knocking or over-advance ignition timing. Misfiring will occur. Power loss and possible engine damage can result. A thorough tune-up with new plugs is necessary.

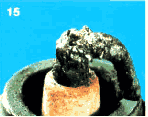

Image 15: The melted ground electrode shown here was caused by pre-ignition. Pre-ignition can result from hot spots in the combustion chamber, over-advanced ignition timing, lean air/fuel mixtures, defective distributor advance mechanisms, deposits in the combustion chamber, defective cylinderhead or manifold gaskets. To avoid pre-ignition, a thorough tune-up is required before installing new spark plugs.

Image 16: The erosion of this center electrode is caused by not observing replacement intervals. Misfiring and poor start behavior will result. Install new spark plugs.

Image 17: The electrode erosion shown here was the result of aggressive fuel and oil additives. It was further aggravated by unfavorable gas turbulence in the combustion chamber caused by heavy deposits. This is not a heat range problem. The effects are hard starting and hesitation on acceleration. Install new spark plugs.

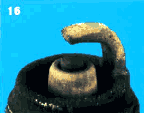

Image 18: This damage is from impact, drop or pressure on center electrode. If the plug has been used for too long, the insulator nose can be cracked by deposits between the center electrode and the insulator and from corrosion of the center electrode. New spark plugs should be installed.

Spark Plugs - Installation

In general, here are some recommendations for installing new spark plugs:

Allow engine to cool.

Disconnect cables/wires. Pull on plug connector only.

Mark spark plug wires if necessary to ensure replacement in proper sequence.

Loosen plugs one or two turns and blow clean surrounding area so that no dirt particles get into the threads or the combustion chamber.

Remove worn spark plugs. If the spark plug is extremely tight, loosen only a little and apply some penetrating oil to seep into exposed

thread, screw the plug in again and attempt to remove it after a few minutes.

Check gap of new spark plugs and adjust if necessary. Always use the vehicle manufacturers recommendation for setting the gap.

Thread in spark plug until hand-tight. Using a torque wrench and suitable spark plug socket, tighten the spark plug according to the

manufacturers torque setting. If a torque

wrench is not available, then tighten ¼ of a turn (90 degrees) for gasket type plugs or 15 degrees for tapered seat plugs.

***

Spark Plugs - Troubleshooting Problems by Sight

Gratis Diens Kwotasie